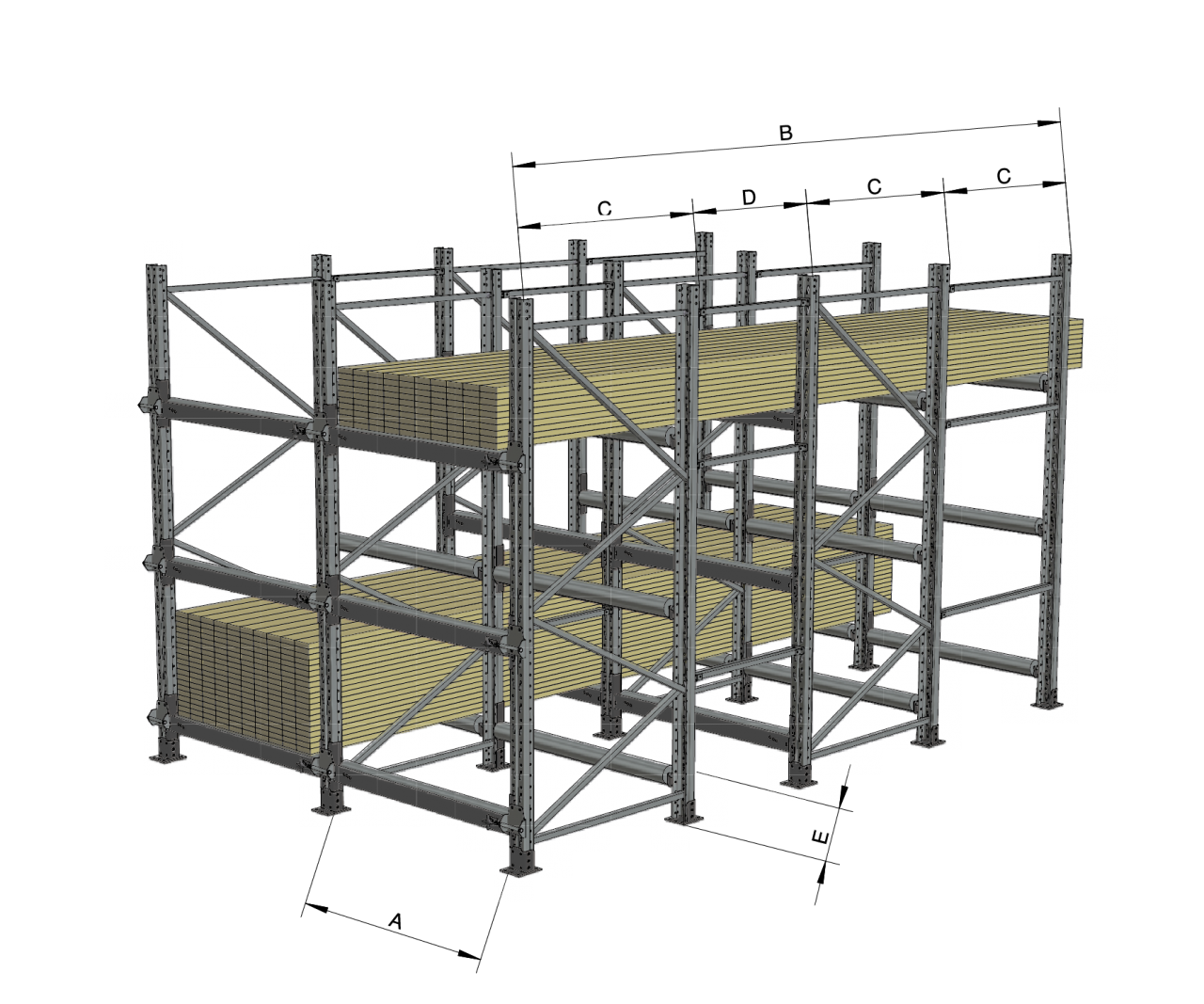

Timber racking

Timber racks give you space to store large quantities of timber in one area (more than in a cantilever racking system). Timber racks can be built either large or small, with one or more picking levels and can be comprised of both roller racks compartments and insertion compartments. If your circumstances change you also have the option to extend or rebuild your timber rack.

EASY ROLL-IN

Timber packages are stored on 5 rollers to accommodate varying timber lengths. The timber package is easily rolled straight into the timber racking.

SAFE AND STYLISH

EAB’s timber racking is compliant with the European Standard for timber racking SS-EN 15635. The timber racking is supplied in different versions depending on whether it is placed indoors or outdoors.

SUPPLIED COMPLETE

The timber racking is supplied complete with posts, braces, carriers and rollers. The accompanying assembly instructions made assembly easy.

Timber packages are stored on 5 rollers to accommodate varying timber lengths. The timber package is easily rolled straight into the timber racking.

You have the option to choose either manual or battery-operated moving carriers for easy and ergonomic handling of the timber. If the moving carrier is not used then two forklift trucks are required for this, which can often become cumbersome and time consuming.

When you need timber racking we usually produce sketches showing what it will look like and how it will function. If you have a builder’s merchant then we will use your blueprints and sketch in our products based on your needs.

SEAMLESS AND ERGONOMIC HANDLING

To avoid problems when loading and to be able to handle a variety of timber lengths the timber packages are stored on five rollers. The timber package is easily rolled straight into the timber racking using a moving carrier.

Made in Smålandsstenar, Sweden

All design, production and development take place under our own roof in Smålandsstenar. This allows us to fully adapt dimensions, appearances and automatics to suit your specific circumstances.

Built to Last®

Built to Last is the promise we give our customers, employees, suppliers and collaborative partners about the solid construction of our products.

Engineering Principles

EAB’s Engineering Principles describe in detail what makes the solutions last from a long-term perspective.

Warehouse safety

At EAB, safety is present from the project start and ensures that the warehouse becomes a workplace what is as safe and sustainable as possible.