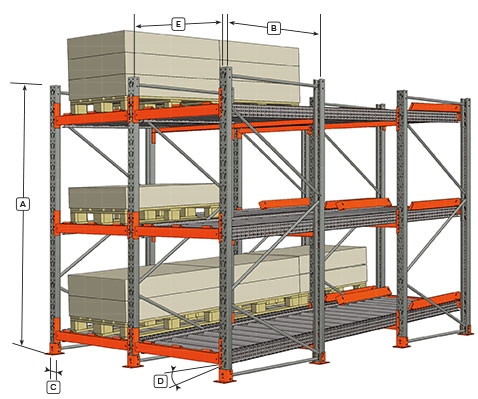

Live storage racking

EAB’s live storage racking are used for highly effective picking of goods on pallet racking in accordance with the FIFO (first in, first out) and FILO (first in, last out) principles. This ensures that the goods are loaded in and out according to a given order, because the right goods always end up at the front, ready for collection.

MAXIMISE YOUR WAREHOUSE SPACE

Live storage racking allow you to minimise the number of truck lanes and maximise your warehouse space.

FIFO OR FILO?

We supply two types of live storage, straight through racks (FIFO) and pushback racks (FILO). The right pallet always ends up in the right place.

WORKS IN ALL TEMPERATURES

Live storage racking are a good choice for cold storage facilities, one-piece flow and multiple parallel flows.

PALLET FLOW RACKS

In straight through racks, goods are managed according to FIFO (first in, first out). The goods are loaded into the pallet rack from one side and unloaded from the other. This provides a very satisfactory flow of goods, for example, when managing goods with a limited storage life. The straight through rack is fitted with brake rollers at regular intervals so that the goods are transported safely.

PUSH BACK RACK

In EAB’s push back rack, goods are managed according to the FILO Principle (first in, last out). The truck pushes the pallets into the rack and loading and unloading take place from the same side. This type of storage only requires one truck aisle, which saves a lot of space as the rack can be placed against a wall.

ALWAYS IN THE RIGHT POSITION

EAB’s inclined roller tracks mean that your goods will always end up in the collection position. This also means the number of truck aisles can be reduced, because the push back rack is an effective high density storage system.

Made in Smålandsstenar, Sweden

All design, production and development take place under our own roof in Smålandsstenar. This allows us to fully adapt dimensions, appearances and automatics to suit your specific circumstances.

Built to Last®

Built to Last is the promise we give our customers, employees, suppliers and collaborative partners about the solid construction of our products.

Engineering Principles

EAB’s Engineering Principles describe in detail what makes the solutions last from a long-term perspective.

Warehouse safety

At EAB, safety is present from the project start and ensures that the warehouse becomes a workplace what is as safe and sustainable as possible.