EAB Built to last®

Learn how to optimize and up to double your storage space

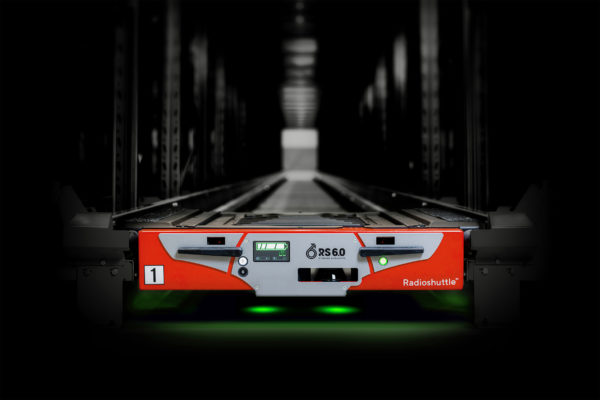

Radioshuttle® is the fully automated pallet management system and may just be EAB's most appreciated solution. Radioshutte®, which currently lifts 70.000 pallets around the world, is revolutionary within the fields of warehousing and logistics, which allows for greater efficiency and better usage of the warehouse area than ever before.

Read about our system Radioshuttle®About EAB

EAB is a global industry leader in providing warehouse storage solutions, doors and steel buildings. Although we have a global presence, we remain a down-to-earth family company with our headquarters, production facility and product development department located in Smålandsstenar, Sweden.

Read more about us Book a consultation

with one of our experts

Book a consultation Work at EAB

– Become one of us

EAB continues its growth, both within Sweden and internationally. That is why we always need to have more employees in our three product areas. Welcome with your application, to any of our offices in the world.

Contact one of our offices BUILT

TO LAST®

Built to last® summarises the way we think and work here at EAB, it is our promise to our customers, employees, suppliers and collaborative partners.

Built to lastlatest news

Fully automated production facility with zero-defect vision

– In one year, at full capacity, the deliveries can cover more than half of all new car registrations in Sweden. Achieving this with a traditional, non-automated setup would require significantly more space and between 100 and 150 people. Today, there are only 24 employees at the factory, says David Ackeby, Plant General Manager at…

Read more newsEAB takes another step towards a more sustainable futureby using emission-free steel for profile product

Steel has a place in the future “At EAB, we are convinced that steel will continue to have a place as a construction material in the future. As a major buyer of steel, we want to take our responsibility by driving and taking an active part in the development of fossil-free alternatives. We do this…

Read more newsNewly installed solar power plant

Our newly installed solar power plant is estimated to produce 795,000 kWh per year and will result in reducing our CO2 emissions by approximately 400 tons per year. An average-sized, electrically heated villa consumes on average 20,000 kWh per year – so our facility is calculated to produce as much energy as 40 such houses…

Read more news