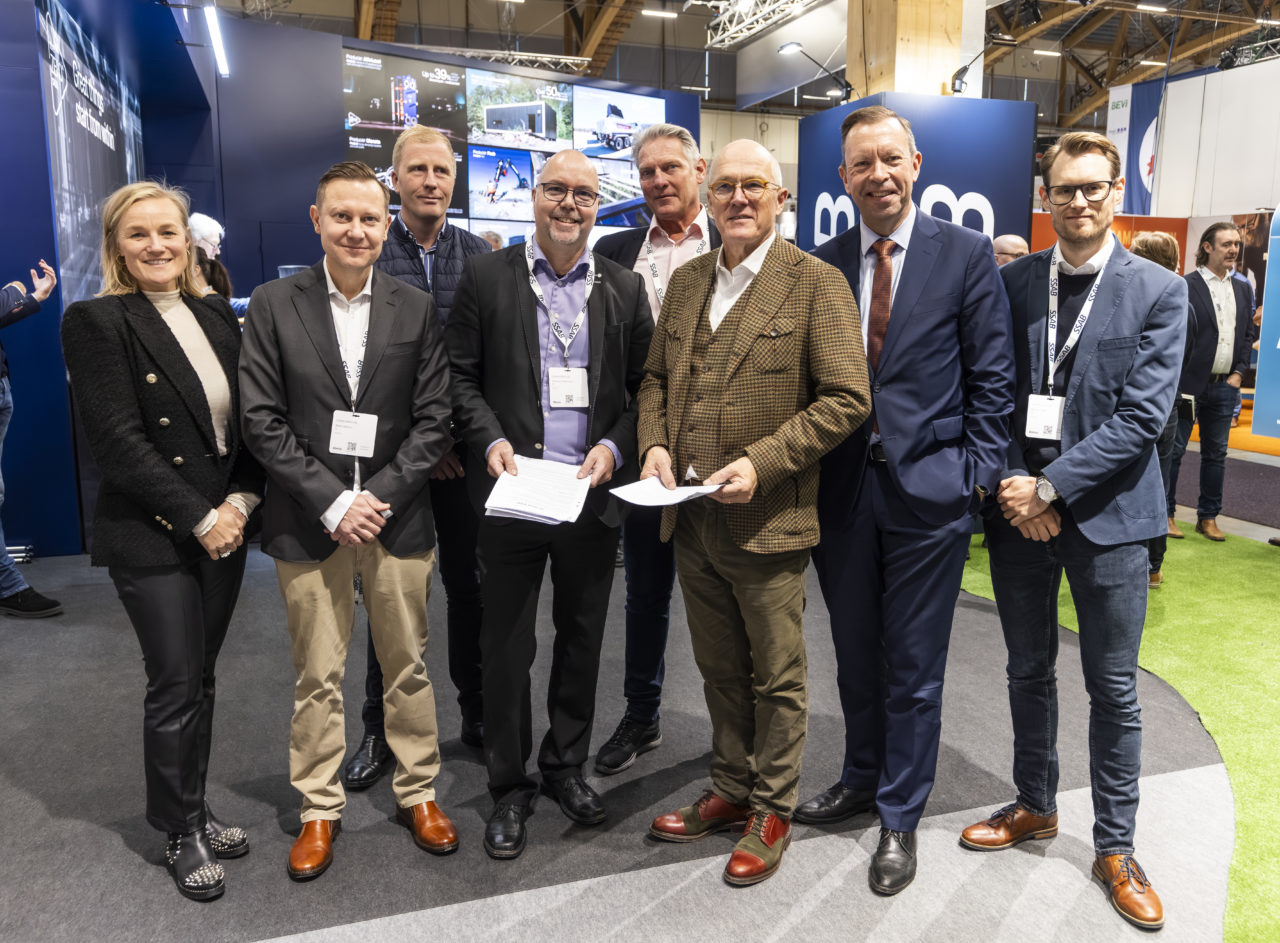

EAB and SSAB form partnership on fossil-free steel

EAB has entered into a strategic partnership with SSAB for the supply of fossil-free steel, including SSAB Zero™, for use across EAB’s core business areas: warehouse racking, doors, and steel buildings. This collaboration marks a significant milestone in EAB’s long-term sustainability journey.

“Our partnership with SSAB on fossil-free grades is an important milestone in our sustainability work, and a signed agreement carries strong symbolic value. It demonstrates our commitment to driving progress – a shared promise to take steel into the future. This is not a journey you make alone. We do it together. And that feels truly inspiring and exciting!

Per-Åke Andersson, CEO EAB Group

RADIOSHUTTLE™ LEADS THE WAY

EAB has already implemented SSAB Zero™ in the chassis of Radioshuttle™, EAB’s flagship product for warehouse automation and a system that has driven EAB’s success internationally. Radioshuttle™ is designed to optimise customers’ storage space and reduce energy consumption, making it a natural starting point for SSAB Zero™.

“We are delighted to deepen our collaboration with EAB, which has already begun using SSAB Zero™ in its production. This proves that fossil-free steel is not just a vision but a reality making a difference here and now. Together, we are taking concrete steps to reduce climate impact and create sustainable solutions for industry.”

Thomas Hörnfeldt, Vice President Sustainability, SSAB

LONG-TERM SUSTAINABILITY FOCUS

At EAB, we design, manufacture, and install warehouse racking, doors, and steel buildings – always in steel and always with a focus on quality, functionality, and longevity. Based in Smålandsstenar, our products are used worldwide. Sustainability is part of our DNA and is about long-term thinking: creating products that stand the test of time. Our goal is to halve our carbon emissions within ten years, and we have already taken important steps with fossil-free energy sources, including our own solar park, sustainable transport, and now climate-improved steel.

Since almost our entire climate footprint comes from the steel we use, partnering with SSAB is a natural step. We want to show that steel is not the problem, but part of the solution for a more sustainable industry. The collaboration is built on openness and innovation: testing new materials, sharing experiences, and developing products together.

SSAB’S OFFERINGS

Traditionell ståltillverkning utgör en betydande källa till globala CO₂ utsläpp. Genom att förändra hur stål produceras vill SSAB minska utsläppen och skapa fossilfria värdekedjor tillsammans med kunder och partners.Traditional steel production is a major source of global CO₂ emissions. SSAB aims to transform steelmaking to reduce emissions and create fossil-free value chains together with customers and partners.

SSAB Zero™ – based on recycled steel and produced using fossil-free energy. Quality and properties match SSAB’s conventional steel. Commercially available since 2023.

SSAB Fossil Free™ steel – the world’s first fossil-free steel, delivered as proof of concept and pilot volumes. Using HYBRIT® technology with hydrogen-reduced iron sponge, the primary source of CO₂ emissions in steelmaking is eliminated, producing water instead of CO₂. Initial exclusive volumes have been supplied to key customers for use in trucks, dumpers, car seats, and watches. The next step is scaling up to industrial level for commercial volumes.

For further information, please contact:

Per-Åke Andersson, CEO EAB Group

+46 70 626 54 00 or +46 371 340 40

per-ake.andersson@eab.se