EAB Det håller®

Port på dagen!

En port med lågt underhåll, hög finish och kort leveranstid - ett löfte med 10 års garanti. Vi har vikportar, slagportar och gångdörrar för omgående leverans från lager.

Kontakta ossOm EAB

EAB är en av branschens ledande leverantörer av lagerinredningar, portar och stålbyggnader, med kunder och försäljning över hela världen. Och samtidigt är vi ett jordnära familjeföretag med huvudkontor, tillverkning och utveckling i Smålandsstenar.

Läs mer om ossBoka rådgivning med en av våra experter

Boka rådgivning Jobba på EAB

– Bli en av oss

På familjeföretagets grund fortsätter EAB sin tillväxt, både inom Sverige och internationellt. Därför behöver vi alltid bli fler medarbetare inom våra tre produktområden.

Lediga jobbMöt våra medarbetare

Vill du veta mer om hur det är att jobba på EAB och vilka möjligheter det finns att växa och utvecklas? Några av våra medarbetare berättar om sitt arbete här hos oss.

Möt våra medarbetareSenaste nytt

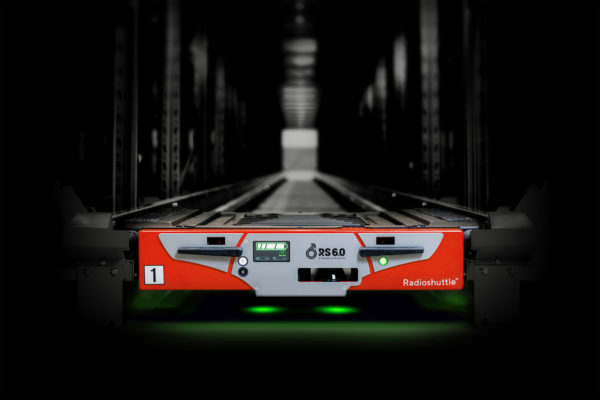

Helautomatiserad produktionsanläggning med noll-fel vision

– På ett år, vid full kapacitet, kan leveranserna täcka mer än hälften av alla nya bilregistreringar i Sverige. Att uppnå detta med en traditionell, icke-automatiserad uppsättning skulle kräva ett betydligt större utrymme och mellan 100 och 150 personer. Idag är det endast 24 anställda på fabriken, säger David Ackeby, Plant General Manager på Gundlach…

Läs hela nyhetenEAB tar ytterligare ett steg i sitt hållbarhetsarbete och använder utsläppsfritt stål till profilprodukt

Stålet en given plats i framtiden ”På EAB är vi övertygade om att stålet kommer att ha en given plats som konstruktionsmaterial även i framtiden. Som stor inköpare av stål, vill vi ta vårt ansvar genom att driva på och ta en aktiv del i utvecklingen mot fossilfria alternativ. Det gör vi dels genom att…

Läs hela nyhetenNyinstallerad solcellsanläggning

Vår nyinstallerade solcellsanläggning beräknas producera 795 000 kWh per år och göra att vi minskar våra CO2-utsläpp med cirka 400 ton/år. En normalstor, eluppvärmd villa förbrukar i snitt 20 000 kWh/år – vår anläggning är alltså beräknad att producera lika mycket energi som 40 sådana villor förbrukar varje år. Nu ser vi fram emot våren!

Läs hela nyhetenFull fart på Räck-Eriks Glänta

Bygget av det nya bostadsområdet på Avenboksgatan här i Smålandsstenar går i full fart! Det är spännande att se de nya hemmen växa fram. På ett av husen muras just nu tegelfasaden, takplåten läggs och fönster sätts in. Den första altandörren är på plats och det kommer att bli ett härligt ljusinsläpp i lägenheterna. –…

Läs hela nyhetenSläpp in ljuset, inte kylan

– De helglasade portarna är de snyggaste man kan ha! Det var ingen tvekan om att det var sådana vi ville sätta in. Eftersom maskinhallen är byggd vid gårdsplanen ville vi att det skulle se ut mer som ett hus än som en lada och det gör det verkligen, säger Mikael nöjt. Maskinhallen är uppvärmd,…

Läs hela nyhetenNP Nilsson storsatsar

Företaget bildades 1907 och ägs fortfarande av samma familj, och nu är det tredje generationen som driver företaget vidare. NP Nilsson har idag ca 190 anställda och omsätter ca 700 mkr. Under 2023 har man i Förslöv färdigställt en storsatsning i form av nytt huvudkontor och ett större logistikcenter. Härifrån kommer man att plocka order direkt…

Läs hela nyheten